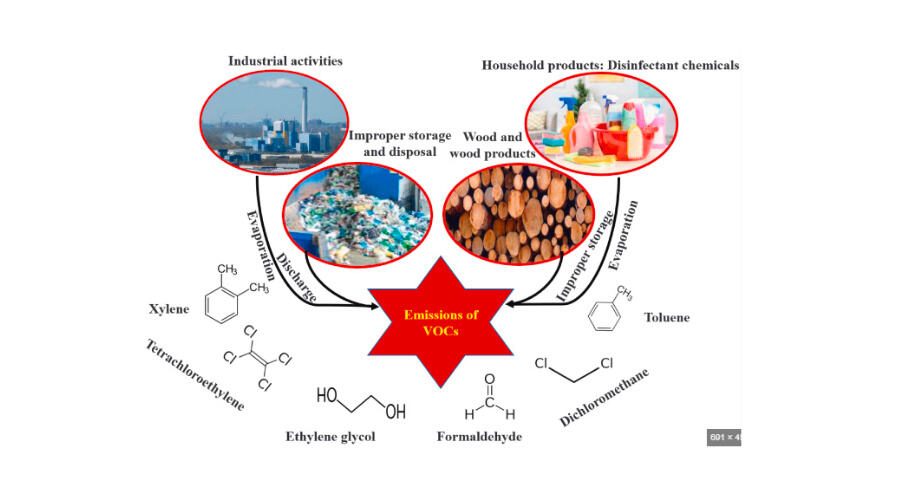

PID (আলোক-আয়নীকরণ ডিটেক্টর) সেন্সরগুলি লক্ষ্যবস্তুর আয়নীভবনের জন্য অতিবেগুনী (UV) আলোর ব্যবহার করে গ্যাসের ঘনত্ব পরিমাপ করে। এগুলি অত্যন্ত সংবেদনশীল এবং উদ্বায়ী জৈব যৌগগুলি (VOCs) শনাক্ত করার জন্য ব্যাপকভাবে ব্যবহৃত হয়।

একটি PID সেন্সরে UV ল্যাম্পের সাধারণত 9.8 eV, 10.6 eV বা 11.7 eV শক্তির স্তর থাকে। ল্যাম্পের শক্তির নির্বাচন লক্ষ্য গ্যাসের আয়নীকরণ বিভব (IP)-এর উপর নির্ভর করে। কার্যকর সনাক্তকরণের জন্য ল্যাম্পের শক্তি গ্যাসের IP এর চেয়ে বেশি হওয়া আবশ্যিক। উদাহরণস্বরূপ, ফরমালডিহাইড (HCHO)-এর IP 10.87 eV। ফরমালডিহাইড পরিমাপ করার জন্য 11.7 eV ল্যাম্প ব্যবহার করা আবশ্যিক, কারণ 10.6 eV ল্যাম্প এটি সনাক্ত করতে পারে না।

উচ্চ আর্দ্রতার অবস্থা (>90% RH) UV ল্যাম্পের জানালায় ঘনীভবন তৈরি করতে পারে, যা পাঠের নির্ভুলতা প্রভাবিত করে। তাই PID সেন্সরগুলি সাধারণত শুষ্ক পরিবেশে ব্যবহৃত হয় বা আর্দ্রতা-প্রতিরোধী বৈশিষ্ট্য সহ ডিজাইন করা হয়।

উচ্চ ঘনত্ব (যেমন, >1000 ppm) বা উচ্চ স্ফুটনাঙ্কের VOC-এর (যেমন তেল, অ্যালডিহাইড এবং সুগন্ধযুক্ত হাইড্রোকার্বন) সংস্পর্শে আসলে UV ল্যাম্পের জানালায় আয়নিত উৎপাদ এবং অনাম্লীয় অবশিষ্টাংশ (যেমন সিলিকন তেল, H₂S) জমা হতে পারে। এটি UV আলোর অভেদ্যতা হ্রাস করতে পারে, যার ফলে সংকেতের দুর্বলতা, প্রতিক্রিয়ার সময় বৃদ্ধি এবং সংবেদনশীলতা কমে যায়। দীর্ঘ সময় ধরে সংস্পর্শে থাকলে UV ল্যাম্পের চিরস্থায়ী ক্ষতি হতে পারে। দূষণ কমাতে, প্রভাব হ্রাস করতে এবং সেন্সরের আয়ু বাড়াতে PID সেন্সর ব্যবহারের সময় পাম্প-নমুনা যন্ত্র ব্যবহার করার পরামর্শ দেওয়া হয়।

গরম খবর

গরম খবর2025-11-21

2025-11-13

2025-11-13

2025-10-29

2025-10-22

2025-10-28